When considering the best material for your truck parking lot, it’s essential to not only think about durability and cost, but also about permeability and the impact of commercial use on your suface over time. How a truck parking surface handles water runoff can affect its longevity and maintenance schedule. In this comprehensive guide, we will delve into the most popular truck parking surfaces, including asphalt, asphalt millings, gravel, and crushed concrete, among others. We will also discuss their longevity and permeability features to help you make an informed decision for your truck parking needs.

Asphalt for Truck Parking:

Advantages

1. Smooth Surface: Asphalt is likely the highest quality surface for truck parking due to its smooth surface and durability. Trucks can make tight turns without concern for creating holes or cracks.

2. Durability: Asphalt is a long-lasting option for truck parking, with a lifespan of up to 30 years when maintained.

3. Quick Set: This truck parking surface sets quickly, allowing for speedy project completion once work commences.

Disadvantages

1. Low Permeability: Traditional asphalt is almost impermeable, typically requiring a drainage system (costly) or slope.

2. Cost: Asphalt is typically more expensive than other surface considerations.

Asphalt Millings for Truck Parking:

Advantages

1. Cost-Effective: These recycled asphalt millings offer a more budget-friendly truck parking surface.

2. Moderate Permeability: Better at handling water runoff compared to traditional asphalt, improving the sustainability of your truck parking area.

3. Low(ish) Maintenance: Typically requires less upkeep than other aggregate truck parking surfaces. Keep a bobcat around and patch holes as they appear with extra milling.

Disadvantages

1. Uneven Surface: It’s difficult to get a milled surface completely graded. As trucks roll over it, you will see some uneven areas appear.

2. Density Variability: Depending on how it was compacted, you will see some areas are “softer” than others and may require more constant maintenance.

3. Availability: May not be readily available for all truck parking projects. Millings are typically recycled from a road that was ripped up. No road resurfacing = no millings.

Gravel for Truck Parking:

Advantages

1. Cost-Effective: Gravel is often cheaper, making it an affordable truck parking surface.

2. High Permeability: Gravel offers excellent water drainage, reducing water accumulation in your truck parking facility.

3. Flexibility: Easy to install and expand, making it a versatile choice for truck parking surfaces. Need to adjust the layout? No problem.

Disadvantages

1. Regular Maintenance: Your gravel truck parking lot will need frequent leveling and top-ups.

2. Dust and Debris: These can become issues in a gravel-based truck parking area.

3. Limited Traction: Can be slippery, especially when wet, affecting truck parking maneuverability.

Crushed Concrete for Truck Parking:

Advantages

1. Recycled Material: A sustainable option for environmentally-conscious truck parking.

2. Moderate to High Permeability: Offers good drainage, reducing water-pooling issues in your truck parking lot when correctly compacted.

3. Cost-Effectiveness: Generally less expensive than hot asphalt or concrete for truck parking.

Disadvantages

1. Surface Texture: Might not offer a smooth surface, affecting the ease of truck parking.

2. Variable Quality: Material quality can be inconsistent.

3. Limited Availability: May not be available in all regions for truck parking projects.

Additional Truck Parking Surface Options:

Pavers for Truck Parking

– Advantages: Aesthetic appeal, can offer moderate to high permeability depending on the type.

– Disadvantages: Higher initial cost and labor-intensive for truck parking areas.

Conclusion

The choice of your truck parking surface involves multiple factors, including cost, maintenance, and crucially, permeability. Understanding how each surface type handles water runoff can save you maintenance costs and contribute to sustainability. Whether you choose asphalt, gravel, or any other material, this guide aims to assist you in selecting the best and most permeable truck parking surface for your specific needs.

Looking for help in designing the layout of your truck parking facility? See this post regarding our layout capabilities or contact us.

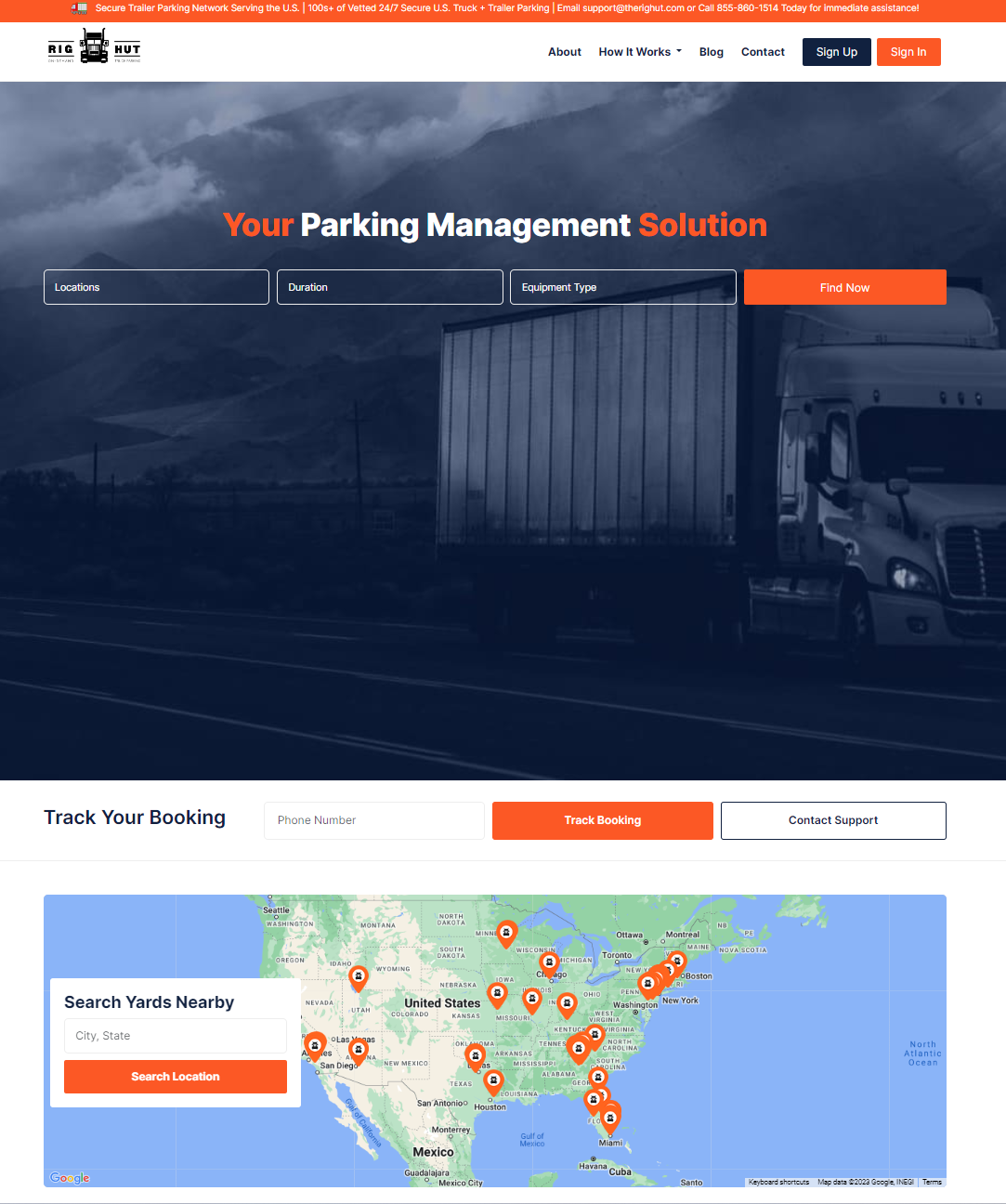

Once you have your yard close to completion, be sure to list the site on our marketplace for maximum exposure.

Looking for yard management software? Click here. Our back end has comprehensive systems to automate communications, payments, and access.